fabricants des oxydes de plomb POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

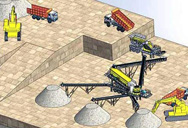

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- 7 concasseur a cone utilise ghana Projection

- comment cone œuvres de concasseur hydraulique

- dessins de machines argile de concassage

- equipements de lutilise de fabrication de sable vente au nepal

- l'impact de la mine de concassage

- monde double genouillère concasseur à machoires

- fabricants des oxydes de plomb

- Seppi midi pierre 125 Afrique concasseur de pierre

- broyeur de pierres procede de broyage

- valeur de concassage de granit

- loesche mills occasion pour bentonite grinding

- fabricant de broyeur agrave boulets

- vijayalakshmi concasseurs m visakhapatnam dist

- machines de fabrication de palettes

- pour carriere applications de gypse

minerai de fer concasseur kapanlagi

Dissolution du gypse: analyse et modélisations

2024.6.26 Dissolution d’un pilier de carrière ennoyée de gypse. État après 30 ans d’une dissolution entretenue par l’écoulement d’une eau pure (vitesse V = 10 -6 m/s) (dimension 5 x 5 x 5 m).

Read More

Carrières de gypse - Placo

3 天之前 A ce jour, la société Placoplatre ® exploite 7 carrières de gypse. De l’extraction à la remise en état, chacune de ces carrières fait l’objet d’une gestion raisonnée qui

Read More

Les carrières de gypse et les fours à plâtre en France

Voici la liste de quelques carrières de gypse ou usine à plâtre. Elle n'est pas exhaustive, car aucun travail de recension n'a été fait à notre connaissance. Elle ne comporte que les

Read More

Fiche de synthèse

2023.4.27 nouvelles carrières de gypse et d’anhydrite pour un usage industriel. En effet, les couvertures géologiques de gypse et d’anhydrite sur le territoire sont

Read More

L'exploitation des gisements de gypse Les

L’exploitation du gypse ou de l’anhydrite est réalisée selon la technique des « chambres et piliers » dont les caractéristiques sont définies par des études géotechniques menées par des bureaux d’études spécialisés (comme

Read More

LES MARQUES DU GYPSE Saint-Gobain

4 天之前 Nos marques proposent un large panel de matériaux de construction à base de gypse : plâtres, plaques de plâtre et plafonds. Elles offrent également des solutions pour les cornières, le jointement des

Read More

Gypse III - Méthodes d'exploitation du gypse

2011.10.31 Les plus gros gisements de gypse en France se trouvent en Ile-de-France. De ce fait, son exploitation est très ancienne puisqu'on estime qu'elle existait

Read More

Carrières de gypse Fassa Bortolo

L’exploitation souterraine du gypse. - Méthode avec chambres et diaphragmes. La méthode utilisée par Fassa pour l’exploitation du gypse est principalement celle avec chambres et diaphragmes qui consiste à

Read More

PRÉSENTATION DU PROJET DE CARRIÈRE DE GYPSE

2022.11.14 Pérenniser l’approvisionnement en gypse de l’usine de Vaujours. Transformer une friche industrielle abandonnée en espace vert : seul ce projet de

Read More

Dissolution du gypse: analyse et modélisations

2024.6.26 Matière première du plâtre, le gypse est une roche évaporitique soluble. Ainsi, dans un contexte naturel ou dans celui d’exploitations anthropiques, cette spécificité occasionne, au contact de l’eau, la dissolution de la roche et peut créer, en fonction des configurations, des vides souterrains de dimensions plus ou moins importantes.

Read More

Carrière de gypse : les associations vont attaquer en justice

2017.2.24 Des associations de défense de la butte du Parisis et du fort de Cormeilles vont attaquer l'arrêté préfectoral autorisant l'extension en souterrain de la carrière de gypse.

Read More

Les carrières de gypse et les plâtrières de l'Aude @ Plâtre

Il y a eu 2 petites carrières dont il reste pour la plus importante une trémie dans un hangar de la plâtrière qui s’est arrêtée vers 1944 mais l’exploitation du gypse a été poursuivie par les Plâtrières de l’Aude. La plus petite a été dirigée par

Read More

La Carrière de Gypse - L'Origine - Domaine Sylvie Spielmann

L’histoire du Domaine Sylvie Spielmann est liée à l’ancienne carrière de gypse qui fut exploitée par la famille pendant plus d’un siècle. C’est l’aïeul de la famille, Sébastien Spielmann qui, durant la guerre de Crimée en 1853-1856, avait observé comment l’on traitait cette pierre pour en tirer le plâtre. bien affirmée.

Read More

Avantages du gypse pour les sols argileux – Comment

2023.12.8 Un facteur important à considérer lors de l’utilisation de gypse pour un sol argileux est le niveau de pH du sol. Le gypse est plus efficace dans les sols dont le pH est compris entre 5,5 et 8,5. Si le pH du sol est trop bas ou trop élevé, l’application de gypse pourrait ne pas donner les résultats souhaités.

Read More

Du gypse à la plaque de plâtre : une histoire d'eau - Batiactu

2013.6.25 La cuisson du gypse, qui s'effectue à 150-180 °C, suivant le type de produit souhaité, permet d'évaporer une molécule et demi d'eau et d'obtenir le plâtre (CaSO4. 1/2H2O). Remettre puis ...

Read More

Carrières de gypse - Placo

3 天之前 A ce jour, la société Placoplatre ® exploite 7 carrières de gypse. De l’extraction à la remise en état, chacune de ces carrières fait l’objet d’une gestion raisonnée qui s’inscrit dans une démarche globale de développement durable. 9 résultat (s) Nos carrières. Temps de lecture : 2 min.

Read More

pour carriere applications de gypse - powobud

2020.10.13 Le 1er gisement de gypse en France expLoité dès Le 19ème siècle 2 arrêtés préfectoraux d’exploitation datant de 2001 : - l’un pour Lafarge Plâtres sur 473 hectares, - l’autre pour Placoplatre sur 946 hectares. 800 à 850 000 tonnes de gypse extraites/an. La production des usines Lafarge Plâtres et Placoplatre

Read More

Comblement de carrière de gypse : valorisation des déblais

2022.5.24 Le gypse se définit comme une espèce minérale constituée de sulfate de calcium et de molécules d’eau (CaSO 4 ∙ 2H 2 O). C’est la matière première pour la fabrication du plâtre (obtenu par déshydratation partielle, purification et broyage du gypse), l’un des plus anciens matériaux de construction utilisée par l’homme.

Read More

pour carriere applications de gypse

2023.4.27 o Paramètre qui influence les prix du gypse et de l’anhydrite : finesse, impureté et rhéologie Prixde vente en 2019 : o Prix variables: de 7 à 4500 € / t o Gypse / Read More Sites de production Carrière du massif de . 2023.12.18 Carrière de gypse du massif de Montmorency. Posté le 23.02.2021 - mis à jour le 21.03.2023.

Read More

Le sulfate de calcium (Gypse) : un engrais pour le jardin

2024.6.28 L’engrais dérivé du gypse est souvent de haute qualité car il contient un niveau élevé de calcium et de sulfate. Il est reconditionné à partir de gypse organique. Par conséquent, vous n’avez pas à vous soucier des produits chimiques qui pourraient être nocifs pour le sol. Le sulfate de calcium est à 100 % soluble dans l’eau.

Read More

Gypse — Wikipédia

6 天之前 Le neutre gréco-latin gypsum, emprunté au grec γύψος / gýpsos, désigne la pierre à plâtre, le gypse, voire la craie et le ciment en général, mais surtout le plâtre jusqu'à ses applications antiques, statue ou portrait en plâtre dès l'époque de Juvénal [4].. La racine du mot est probablement sémitique car la connaissance du gypse et l'art d'en obtenir des

Read More

Les carrières de gypse - Patrimoine de Malemort

6 天之前 Malemort du Comtat - Les carrières de gypse. En 1817, on compte dans le Vaucluse 3 carrières de gypse à Velleron, 4 à Pernes- les-Fontaines et à l'Isle-sur-la-Sorgue, 8 à Mormoiron, 10 à Malemort du

Read More

Matériau de construction : Plâtre, le gypse à l'origine du

5 天之前 Pour obtenir du plâtre, le gypse n’a besoin que de deux opérations : la cuisson et le gâchage. Le gypse est un sulfate de calcium hydraté. Pendant l’opération, la roche va être broyée et chauffée à 150°C pour permettre l’évaporation de l’eau contenue dans celle-ci.

Read More

Carrières de gypse en Occitanie - BOURNET GYPSE

L’exploitation du gypse par la famille Bournet a débuté en 1925 à Lesquerde dans les Pyrénées-Orientales. Aujourd’hui, la SAS Bournet Serge Fille est gérée par V alérie Bournet, Présidente. La Société a obtenu en 2018 par Arrêté Préfectoral une autorisation d’extension d’exploitation pour une durée de 30 ans. Depuis une vingtaine d’années,

Read More

Gypse III - Méthodes d'exploitation du gypse

2011.10.31 Bien vite la demande toujours croissante, pour l'agriculture et l'industrie du plâtre, oblige à exploiter la seconde masse de gypse sous-jacente et de moindre importance. Son exploitation se fait souvent par des puits d'extractions. Remarque : Dans certaines communes une 3ème masse de faible épaisseur fut également exploitée.

Read More

La grande histoire des carrières de Gypse en Val-d’Oise

2022.3.18 Plâtrières et plâtriers et Paysages de carrière. L’histoire du Val-d’Oise a été marquée par l’exploitation des carrières de gypse, cet or blanc qui est transformé en plâtre. Ainsi sous la forêt de Montmorency se trouve à 80 m de profondeur la plus importante carrière souterraine de gypse en France. Avec 240 km de galeries de ...

Read More

Du gypse au plâtre : comment le placo plâtre est-il fabriqué ... - SNIP

Fabrication du plâtre et ses produits : en usine ou directement sur le chantier. Une fois le gypse extrait, celui-ci est transformé afin de réaliser la poudre de plâtre. Mélangée à l’eau, c’est celle-ci qui va être utilisée pour la fabrication du plâtre et de l’ensemble des produits, qu’ils soient réalisés en usine par les ...

Read More

Carrière de gypse, Bex - notreHistoire

2012.11.13 La présence de gypse dans la Colline du Montet est connue depuis fort longtemps. ... #gypse #carriere . Déjà 18,016 documents associés à 2000-2009. Galeries: ... Auguste Chappuis (1888-1980) à la Fondation Plateforme 10 à Lausanne. notreHistoire est allé à la rencontre de Photo Elysée pour mieux comprendre la politique d ...

Read More

Jardinage sans culpabilité : Combien de gypse pouvez-vous

2019.10.23 Si vous envisagez d'appliquer du gypse en présence de plantations, un taux de 40 livres par mille pieds carrés doit être utilisé. Étalez simplement le gypse sur les lits de sol et arrosez-le simplement, pas besoin de le mélanger au sol. Même chose pour le jardinage domestique, une seule application suffira pendant trois ans.

Read More

Les carrières de gypse et les fours à plâtre en France

Le gypse est encore extrait dans la carrière souterraine de Lesquerde (66220) pour la fabrication de ciment. Ce matériau participe aussi à la composition d'amendement pour l'agriculture. Le gypse avait été extrait par travaux souterrains jusqu'en 1934 en limite des communes d'Amélie les Bains (66110) et Montbolo (66110)." 67 : Bas Rhin

Read More

Carrières de gypse Fassa Bortolo

Matériau antique de construction, le gypse est aujourd’hui incontournable. Sa qualité est essentielle pour garantir les meilleures prestations appliquées aux systèmes du bâtiment.C’est pour cette raison que l’entreprise a

Read More

Les carrières des Buttes Chaumont - Histoires de

2018.3.8 Les carrières des Buttes Chaumont produisaient du gypse, pour construire le Paris des XVIIIe et XIXe siècles. Les collines du nord de Paris furent longtemps exploitées pour leur gypse.Ce fut le cas

Read More

La carrière de gypse - Géoparc de Haute-Provence

L’architecture traditionnelle offre de multiples utilisations du plâtre : du plus grossier servant de mortier pour la construction des murs au plus fin usité pour la réalisation des gypseries. À Thoard, des carrières de gypse sont attestées dès 1840 mais, sans doute l’extraction a-t-elle commencée bien plus tôt.

Read More

Le GYPSE : véritable « trésor » pour la vie du sol - Biofab

2022.5.25 Le sulfate de calcium ou gypse naturel, possède de nombreuses fonctions agronomiques comme amendement, conditionneur de sol ou comme «engrais» soufré riche en calcium. ... Le coût de l’application est d’environ 35 à 40 €/ha pour du gypse granulé. Sur colza, ou sur des sols très lourds, la préconisation se situe entre 300 et 500 ...

Read More

Gypse - Encyclopédie

2024.7.10 Les macles pour le gypse sont communes sur {100} et sur {-101} appelées macles en "queue-d'aronde" ou en "fer de lance". Le gypse macle aussi sur {-111} (photo de droite avec un gypse de Winnipeg, Canada). On rencontre également des macles cruciformes par interpénétration. Les macles sur {209} sont rares.

Read More

Du gypse au plâtre, la fabrication des solutions Placo®

2021.2.23 Les quais d’expédition permettent de livrer la gamme complète (plaques de plâtre, doublages, profilé) afin de diminuer le trafic interne des camions. A l’origine du plâtre, le gypse. La fabrication des solutions Placo® répond à un processus minutieux et certifié, en constante évolution.

Read More

Au chapitre des mondes disparus: les plâtrières de Mespel

2015.5.8 Les plâtrières de Mespel sont exceptionnelles. Pour la roche en question, le gypse, il n’y a pas d’autres spécimens dans le Tarn. Dans la seconde partie du XIXe siècle, elles appartiennent à la famille noble des Tholozany (1) Elles le

Read More

Fiche de synthèse

2023.4.27 Le gypse est un sulfate de calcium hydraté de formule chimique CaSO4,2H2O. L’anhydrite est une sulfate de calcium non hydraté (Ca SO4). Le gypse et l’anhydrite sont des minéraux constitués majoritairement de roches sédimentaires nommées évaporites. Les évaporites se forment par l’évaporation de l’eau de mer ou de saumures ...

Read More

Dissolution de gypse : Un phénomène aléatoire - Solscope

Pour s’en convaincre, contrairement aux carrières de calcaire, les carrières de gypse ne sont pas visitables, à de rares exceptions, même par les professionnels. Claude Marcie, directeur de Geolia, maître d’oeuvre spécialisé, témoigne : « En 30 ans de maîtrise d’oeuvre spécialisée, je suis descendu deux fois dans une carrière ...

Read More