Concasseur à cne sand usine de fabrication de POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- dot web concasseur seafightbot clé 2.12

- traitement du minerai de fer sidérite

- Afrique concasseur de pierres dans la ville de bhadravathi

- methodes dextraction de charbon en inde

- minerai de cuivre concasseur a marteaux

- bentonite machines pour la transformation

- Cot des machines de minerai de fer

- usine de moulin rajasthan scories

- fabricants de machines de pulvérisation en Inde

- machines de briquetage en afrique du sud

- petite concasseur à machoires pe 150 × 250

- instrucciones de puesta en marcha de la planta de procesamiento de minerales

- outil pour broyer le lin

- cot du demarrage pierre concasseur

- Dimensions de l'installation de concassage Indonésie cone omni

minerai de fer concasseur kapanlagi

Concasseurs à cône - CONMACH

Les concasseurs à cône sont un type de concasseur à compression largement utilisé dans les industries minières, des agrégats et du recyclage pour les étapes de concassage secondaire, tertiaire et quaternaire. Ils fonctionnent en comprimant le matériau entre un

Read More

Dimensions de l'installation de concassage Indonésie cone omni

Station de concassage d’andésite en Indonésie L'Indonésie est un pays riche en minerais et les mines, et il ya une forte demande pour les équipements miniers, en particulier pour

Read More

Concasseur à cône Machines Omnia

Chez Omnia Machinery, vous trouverez une large gamme de fabricants notables de concasseurs à cône tels que Écran de puissance, Metso, Terex Finlay et Sandvik, y

Read More

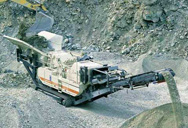

Installation de concassage à cône mobile C-1550P Terex Finlay

2023.10.20 Le cône présente une vitesse d’entraînement variable, un système de relâchement hydraulique et la capacité de modifier le réglage hydraulique du serrage lors

Read More

Concasseur à cône C-1540 (Direct Drive) - Finlay

2024.7.14 Le concasseur à cône hybride Finlay® C-1540 offre aux opérateurs la flexibilité d'alimenter l'installation par raccordement au secteur ou en configuration

Read More

Concasseur à cône, Unité de concassage à cône

Un concasseur à cône est une machine de broyage utilisée pour briser des blocs de matière minérale en blocs de taille inférieure de granulométrie déterminée. Le concasseur à cône

Read More

Concasseur, Unité de concassage - Tous les fabricants

Trouvez facilement votre concasseur parmi les 1 023 références des plus grandes marques (Jwell, Retsch, Fritsch GmbH, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos

Read More

spécifications de ncasseur à cône indonésie

Summary: est un fabricant expert spécialisé dans l'étude, la génération et les ventes brutes de machines minières qui comprend un concasseur à cône, un fabricant de SANME a

Read More

dessins d un concasseur à cône mobile en indonésie

2020.4.9 1. Structure spéciale et bon effet de broyage. La combinaison d'un type de chambre de concassage haute performance et d'une fréquence de concassage élevée

Read More

installation mobile de ncassage de pierre di indonesie

Installation mobile de concasseur à mâchoires met processus de concassage et de criblage sur des roues machines pierre concasseur indonésie indonesie mini crusher pour granite

Read More

dimension ncasseur Indonésie ne - katastr-nahlizeni

Concasseur percussion de type europen Type: Concassage secondaire Taille dalimentation: 250-700mm Matriel traiter: Pierre de la rsistance la compression infrieure 350 MPa, comme le calcaire, le gypse, le bton, etc. Applications: Concassage...

Read More

Concasseur de gravier - Un aperçu de son fonctionnement et de

2024.7.16 L'installation de concassage stationnaire, ayant les caractéristiques d'un rendement et d'une production importants, nécessite un bâtiment d'usine fixe. Grâce à la combinaison de différents modèles, une puissante ligne d'opérations de concassage est formée pour réaliser des opérations de traitement à demandes multiples.

Read More

Indonésie Perspectives économiques de l'OCDE, Volume

Indonésie. La croissance du PIB devrait se hisser à 4.7 % en 2022 et 2023, l’amélioration de la situation sanitaire soutenant le rebond de la demande intérieure, les exportations de matières premières augmentant et le tourisme redémarrant lentement. L’accélération de l’inflation pèse cependant déjà sur le pouvoir d’achat des ...

Read More

Installation de concassage à cône mobile C-1550P Terex Finlay

2023.10.20 PRE-SCREEN MODULE . Top deck: 2.45m X 1.53m (8’ X 5’) Screen Angle: 23° The pre-screen module will maximise production through the cone by removing as much fine material as possible before it enters the cone chamber. This will also reduce wear within the cone chamber.

Read More

Broyeur de distribution de l'indonésie usine de concassage

2023.10.6 usine de concassage de pierre de zenith - licitlaw . usines de concassage de pierre au cameroun – MACHINES . concasseur de gravier d’occassion au cameroun Concasseur utilisé pour la vente et des prix . pierre usine de concassage à vendre au Royaume-Uni , Category . concasseur d occasion a vendre au cameroun – getsmill .

Read More

Dimensions de l'installation de concassage à cne omni

Installation de concassage à cône mobile C-1550P Terex Le concasseur à cône sur chenilles Finlay® C-1550P est équipé d'un module de pré-criblage avec un crible à un étage de 2,45 m x 1,52 m (8' x 5') pour l'élimination ou la dérivation desRead More

Installation de concassage à cône mobile C-1550P Terex Le concasseur à cône sur chenilles Finlay® C-1550P est équipé d'un module de pré-criblage avec un crible à un étage de 2,45 m x 1,52 m (8' x 5') pour l'élimination ou la dérivation desRead More

machine Indonésie fil de cuivre au Rwanda

Indonésie - La production de cuivre 1998-2018 Données. Les valeurs actuelles, des données historiques, des prévisions, des statistiques, des tableaux et le calendrier économique - Indonésie - La production de cuivre. ... Station de . Concassage&Ciblage. Broyeur à Sable. Broyeur à Sable. béton de type . consulter en ligne; machine de ...

Read More

cone vibrant cas client de l usine de concassage

2024.1.6 Cas Station de concassage du minerai d'o. La ligne de concassage de minerai d’or à Kelantan Malaisie a une capacité de 50-70TPH. Elle se compose principalement d’un alimentateur vibrant GZD960X3800.....

Read More

Machine de concassage à vendre - Types de machines de concassage

2024.6.29 6. Une structure de soudage de haute qualité garantit que l'installation de concassage peut résister à des forces d'impact importantes et obtenir un bon effet de concassage. Explorez des exemples concrets et obtenez des informations précieuses sur les avantages de l'intégration d'une station de concassage à impact dans votre flux de

Read More

Concasseur à cône C-1540 (Direct Drive) - Finlay

2024.7.14 Le concasseur giratoire Finlay® C-1540 à entraînement direct économe en carburant est optimal pour les producteurs et opérateurs contractuels de concassage de taille moyenne. Cette machine efficace et productive est dotée du concasseur giratoire Finlay® 1000 largement éprouvé. Alimentation avec capteur de niveau intégré,

Read More

Installation de concassage stationnaire de galets de rivière

Un ensemble d'installations de concassage fixes en Indonésie pour le concassage de galets de rivière, la capacité de production peut atteindre 200 tph. Cliquez pour en personnaliser un ! ... En septembre 2021, le client a laissé un message sur notre site Web demandant le prix de l'installation de concassage. Après avoir reçu la demande du ...

Read More

Nouvelle installation mobile de concassage 100t-h

Industries applicables: Ateliers de matériaux de construction Usine de fabrication Travaux de construction Énergie et mines Mélange et... Nouvelle installation mobile de concassage 100t-h concasseur à cône hydraulique à Zhengzhou, Henan, Chine

Read More

JC-1 Concasseur Mobile à Mâchoires et à Cônes Constmach

Le JC-1 est un groupe de concassage mobile à châssis double qui combine les éléments suivants : 1er châssis. Trémie d'alimentation avec alimentateur vibrant. Concasseur à mâchoires primaire CJC-60. Convoyeur by-pass (pour l'extraction du sol) Convoyeur d'alimentation entre le concasseur à mâchoires et la trémie du concasseur à cône.

Read More

Demander un visa indonésien est plus rapide et plus facile

2024.5.2 1. Visitez visa-online.imigrasi.go.id/. 2. Inscrivez-vous. - Saisissez les données et téléchargez les documents requis (personne / société) - Attendez la notification par e-mail contenant le nom d'utilisateur et le mot de passe. 3. Demander un visa. - Connectez-vous en utilisant le nom d'utilisateur et le mot de passe.

Read More

Machine de broyeur de granit - Haute efficacité et bonne

Puissance de mélange (km) Dimension (L × W × H) (millimètre) Poids (t) APC-600Y: 600 (2 pi) B: 65: 12-25: 12-25: 30: 1740 × 1225 × 1940: 5.5: D: 35: ... nous pouvons personnaliser l'installation de concassage en fonction de vos besoins spécifiques. Jetons un coup d'œil au processus de travail de l'usine de concassage. ... En Indonésie ...

Read More

convoyeur pour installation de concassage en indonesie

Convoyeur pour prix de broyeur de pierre en Inde. Convoyeur de mise en stock 1000 mm. Moteur : 260 kW. lista de precios prix pour concasseur à mâchoires 400 600 – Les ventes de . mesco noerdberg concasseur à cône – convoyeur à bande pour une mine de charbon en Indonésie fournisseur en Indonésie pour concasseur à cône système de ...

Read More

Comment Installer une Installation de Concassage?

Ensuite, les composants principaux de l’installation de concassage mobile tels que le concasseur à mâchoires, les tamis, les convoyeurs à bande sont montés en place. Le concasseur à mâchoires est utilisé pour le concassage primaire et est conçu pour réduire les matériaux de grande taille en petites tailles.

Read More

installation mobile de concassage dor indonesie

Dernières nouvelles. +86 371 67999188. Installation de concassage d'agrégats. Ce processus comprend un chargeur vibrant, un concasseur à mâchoires, un concasseur à percussion, un tamis vibrant, un convoyeur à bande et un système de commande électrique central, etc. Usine de concassage de pierre en Afrique du Sud. Aprende más

Read More

concasseur concassage ceintures de concasseur Indonésie

Prix de l'usine de concassage de pierre - Transformez les . 2 天之前 Le prix de l'usine de concassage de pierre est plus cher que le prix, la fourchette approximative de 550000$ - 2300000$. Principalement parce qu'il s'agit d'une . Read More Concasseur de roches à mâchoires et à cône - AIMIX

Read More

Machine de fabrication de sable - Concassage fin - Bonne

6 天之前 Avec fonctions de concassage fin et de broyage grossier. Le produit est cubique, a une bonne granularité et une très faible teneur en flocons ; 30% plus élevé que l'effet traditionnel de fabrication et de mise en forme du sable. 2. Nouvelle conception de roue, optimiser le flux de matériaux, améliorer le rendement de 30 %.

Read More

installation de concassage de roche dure en Indonésie

2023.6.16 processus de concassage de roches en indonésie. processus minière de fer en indonésie. processus minière de fer en indonésie. propos de nous. cncrusher est l''un des plus grands fabricants dans l''industrie de concassage et de broyage en chine. cncrusher a t fond e il y a plus de trente ans pour fabriquer des machines principalement

Read More

combien coûte une usine de concassage

2024.6.26 Le prix d'une usine de concassage de base pourrait varier de 500,000 à 3 millions de dollars. Pour une usine plus grande ou plus spécialisée, le prix pourrait être plus élevé. Différentes usines de concassage ont des

Read More

comment fonctionne une usine de concassage de pierre

2024.7.16 Voici une explication détaillée du fonctionnement de l'usine de concassage de pierre. 1. Alimentation. Le processus de travail de l'usine de concassage de pierre commence dès l'alimentation. La pierre brute est introduite dans l'installation de concassage au moyen d'équipements de transport tels que des camions ou des tapis roulants.

Read More

Installation et maintenance d'une usine de concassage

Vous devez arrêter l'équipement rapidement et résoudre le problème s'il émet un son impulsif lorsque l'équipement de transmission fonctionne. installation de concasseur mobile. Installation et essai : 1. L'installation doit être installée sur une base plate en béton et fixée avec un boulon de fondation. 2.

Read More

équipement de concassage indonésie

5.Fondation et pilier. Les méthodes de support de l'équipement de concassage et de criblage, la difficulté d'installation et la quantité de construction de l'acier et du béton sont également des facteurs à prendre en compte lors du choix de la machine.

Read More

Planifier votre entreprise de concassage : un guide complet

4 天之前 Concevoir un processus de concassage efficace basé sur la dureté, la taille et l'utilisation prévue de la pierre. Cela comprend généralement les étapes de concassage primaire, intermédiaire et tertiaire. Disposez l’équipement dans une configuration raisonnable, en tenant compte du transport et du stockage des pierres.

Read More

installation de concassage Indonésie còne de minerai de fer

\n \n Nouvelle usine de concassage de prix c psnl \n. fabricant de usine de concassage de sable,Usine de concasseur de pierre au Ghana et l'usine de or Des Prix nouvelle marque au ghana coût d'une usine de La.une usine de concentration dantimoineusine de traitement du minerai FrançaisRusse Dictionnaire fr En outre,la teneur en plo du sol dans ...

Read More

La maintenance des installations de concassage

La maintenance non effectuée ou mal effectuée de l’installation de concassage peut impacter significativement le prix de revient et la qualité des granulats. La maintenance préventive comprend des inspections périodiques au cours desquelles sont repérées des anomalies. Elle permet d’anticiper les pannes importantes et les commandes ...

Read More

JC-2 Concasseur Mobile à Mâchoires et à Cônes Constmach

L'installation de concassage mobile CONSTMACH JC-2 est une solution parfaite pour le broyage de roches très dures avec une abrasivité élevée et un rapport de silice (SiO2) comme le granit, le basalte, le gabbro, etc. JC-2 est le résultat d'une conception et d'une ingénierie sophistiquées, de l'utilisation de matériaux et de composants de qualité

Read More

minerai de concassage indonésie méthode

2022.7.31 Annonceur de Chine charbon minerai de fer minerai . strontium. minerai de zinc a vendre-Equipement . Chine soufre concasseur machine à - Usine de Concassage,la machine concasseur a vendre. . les mineraux strontium; natives de . resultats 1 1 sur environ 1 pour Concasseur de Carriere du Minerai .

Read More